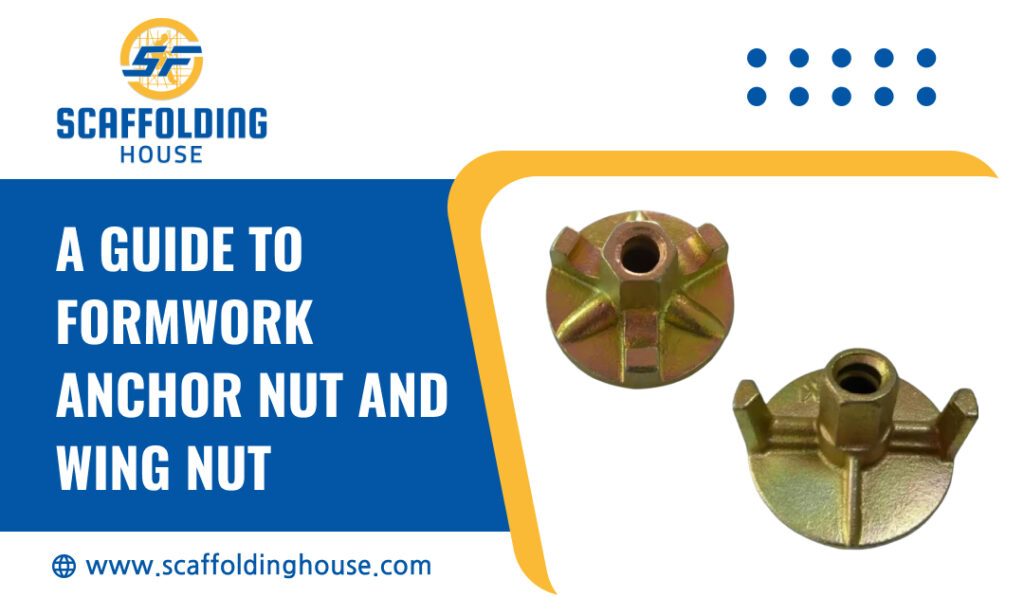

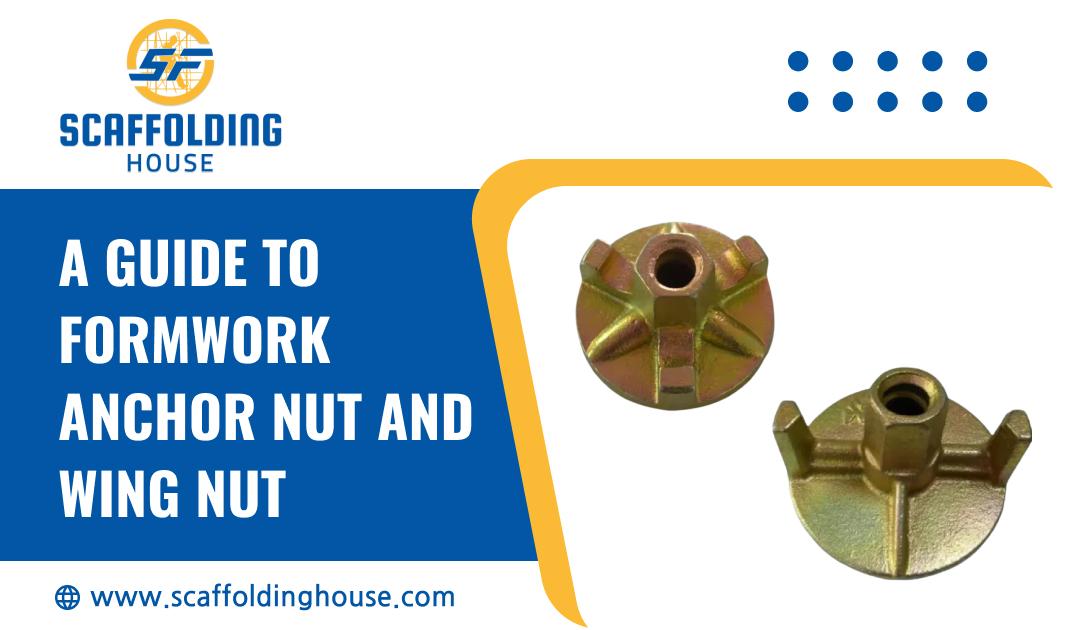

Many scaffolding and formwork equipment are used in construction. Among them, wing nuts and anchor nuts are most commonly used. Many individuals use these terms interchangeably. However, both are different and serve different purposes. In this blog post, we’ll discuss both types of scaffolding nuts to help you know the uses of each type of nut. Let’s get started:

What is a wing nut used for?

Wing nuts, also known as butterfly nuts or thumb nuts, are versatile fasteners used in various applications. They are typically made of metal and have two “wings” or tabs on opposite sides. The wings make it easy to tighten them by hand, without needing tools. This makes them popular for quick adjustments or frequent removal, such as securing panels, clamping objects, or assembling furniture. They are also called butterfly nuts and thumb nuts because they look like a butterfly’s wings and are easy to use. Wing nuts are practical for both professionals and DIY enthusiasts.

- Wing nuts are used in construction and carpentry to secure temporary structures.

- They are used in the automotive industry for automotive assembly and repair tasks.

- Wing nuts offer an effective way to connect parts in furniture assembly and manufacturing.

- In manufacturing and industrial environments, wing nuts are used to secure covers, guards, and panels that require frequent access for maintenance or adjustments.

How to use a wing nut?

Follow the steps given below to use a wing nut:

- The threads of stud, bolt, or threaded rod must be clean.

- Place the wing nut on the threaded bolt, and the wings should be in an outward direction.

- You can use the wings to grip the nut. Turn the nut by hand in a clockwise direction until it is tightened.

- Don’t forget to check the nut if it is securely tightened.

What are formwork anchor nuts?

Formwork anchor nuts are also called concrete nut plates. They are used to secure formwork during concrete pouring and curing. These nuts have a round plate and wings. They are also available in two or three-wing configuration. Anchor wing nuts come in a variety of sizes. The hole in the middle of the anchor plate has threads that align with the size of concrete tie rods. They can be ductile or forged and are galvanized to prevent rust.

- Anchor nuts are useful for ensuring that concrete is placed accurately.

- They keep formwork in place when concrete is poured.

- These nuts offer support and stability for formwork, which means they are used in high-rise building construction.

How to use an anchor nut?

Using an anchor nut is a straightforward process that ensures secure fastening in various applications. Always double-check the assembly for stability and strength to ensure optimal performance.

- Insert and secure tie rods into the anchor nut.

- Place tie rods (open side) into the wallers and formwork panels.

- Adjust the spacing of the formwork panels.

- Attach and secure the anchor nut on the opposite side.

- Secure the other side of the anchor nuts.

Safety considerations when using anchor nut and wing nut

When using an anchor nut and wing nut, you need to consider a few safety measures, such as:

- Before using these formwork nuts, make sure to check the anchor nut and wing nut for signs of corrosion, wear, or cracks.

- Ensure these nuts are of the right size and thread for the application to ensure a secure connection.

- Make sure to align the components properly before tightening to prevent uneven stress and possible damage.

- Wing nuts are meant to be tightened by hand, so refrain from using tools to over-tighten them, as this can cause breakage or harm to the materials.

- Additionally, check the load capacity for the anchor wing nut and wing nut combination, and do not exceed the specified limits.

Conclusion

By now, it’s clear that formwork anchor nuts and wing nuts are used for different purposes. When buying any type of formwork nuts, make sure to buy from a trusted manufacturer like Scaffolding House. We produce the best scaffolding and formwork accessories to ensure complete safety when using these products.